What is a Cannabis Extraction Lab?

Once cannabis is grown and harvested, solvent or solventless methods can be used to separate THC, CBD and cannabinoids, among others, from the cannabis plant, leaving an oil-like extract that can be used for create a variety of products including oils, tinctures, capsules, vaporizer cartridges, hash, shatter, wax, infused edible and topical forms, and more. Extraction labs can either exist independently or be part of a vertically integrated cannabis operation. You will need a cannabis processor or a manufacturer license to process cannabis into a concentrated form.

Cannabis Extraction Methods

Solvent-based cannabis extraction uses different types of solvents, such as butane, propane, ethanol, or supercritical carbon dioxide (CO2). Primary extraction separates cannabinoids and terpenes from unwanted plant matter. Next steps may include color remediation, winterization, filtration, and terpene removal to purify your cannabis extract. Decarboxylation, distillation and crystallization can be used for isolation, refinement, and purification to create a finely tuned product.

Solventless extraction methods use heat, pressure, ice, or water. The rosin pressing technique separates the resin from the plant material using heat and high pressure. The plant material is fresh frozen before using as a solventless starting point without; this preserves more of the volatile terpenes of the cultivar that is converted into a concentrated product. Rosins can be manufactured into a variety of textures resembling shatter, wax, budder, crumble, and other extract types. Ice water extraction separates trichomes from flowers or trim using ice, water and silk-screen filters. Bubble hash can be used in a vaporizer, bong, pipes, in the joint itself, and can also be mixed with butters to produce edible forms.

Cannabis Extraction Business Setup Costs

The cost of setting up a cannabis extraction business varies greatly depending on the type and scale of extraction. For flammable solvents, build-up costs alone can be over $300 per square foot due to stringent facility requirements, while extraction equipment using non-flammable solvents is more expensive compared to hydrocarbon and ethanol extraction equipment. Solventless extraction systems are much cheaper at first glance, but require more labor and energy compared to the product yield. In our example, we are considering a small laboratory with a capacity of about 100 pounds of dry material per week. The resulting production is estimated to be:

- BHO wax, shatter, crumble: 500 grams per week,

- Rosin: 250 grams per week,

- CO2 oil: 1,500 grams per week,

- Ethanol oil: 1,250 grams per week.

Capital Costs

- The building infrastructure is estimated at $75,000.

- The extraction and refining equipment is estimated at $600,000.

- A buffer of $37,500 is incorporated to account for ancillary items.

The Economics of Cannabis Extraction

The operational costs of a cannabis extraction business include the costs of material, electricity, labor and packaging, lab testing and transportation, other direct costs, as well as indirect operating costs such as administrative, marketing, distribution, taxes, interest and other expenses that vary depending on the location.

Direct Costs

- From a purely manufacturing standpoint, our cannabis extraction business will employ an extraction manager and four laboratory technicians. The extraction manager has estimated salaries of $80,000/year, while the laboratory technicians have estimated salaries of $45,000/year.

- The assumed/estimated material costs, including plant material, is about $1,427,005/year.

- The total cost of electricity for our cannabis extraction facility is estimated at $115,000/year.

- Other costs, including packaging and testing, is about $50,000/year.

The sum of running costs for our extraction facility with these assumptions would be $1,852,005/year.

Extending our model to determine break-even points for capital expenditure plus direct and operational costs suggests that our laboratory will recoup the total at week 65. Finally, in the third year, our extraction facility is expected to receive a net profit of $844,342 based on this model.

Revenue = $4,005,450 (100%)

-Direct Costs = $1,852,005 (46%)

Gross Profit = $2,153,445 (54%)

– Operating Expenses = $680,338 (17%)

Operating Income = $1,473,107 (37%)

– Depreciation, Interests and Income Tax = $628,765 (16%)

Net Income = $844,342 (21%)

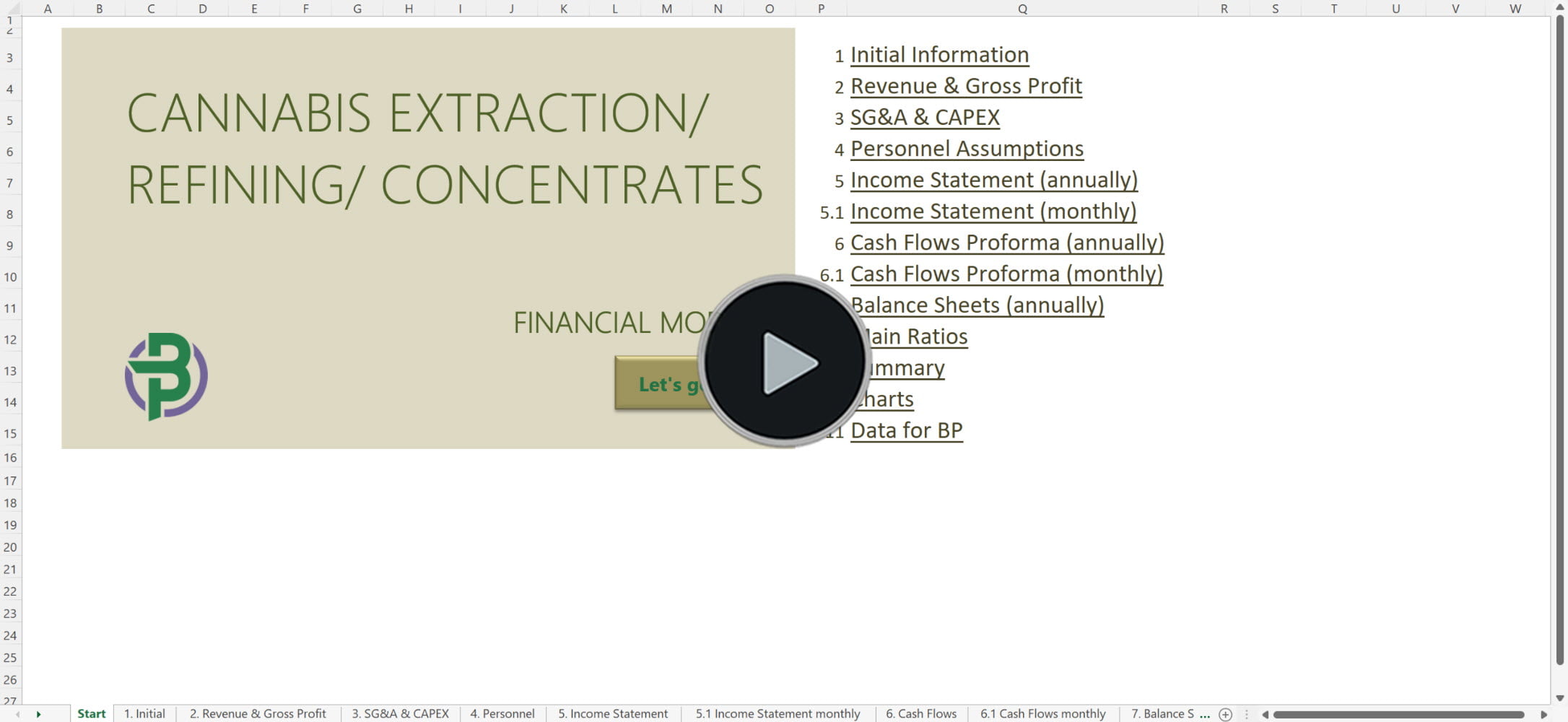

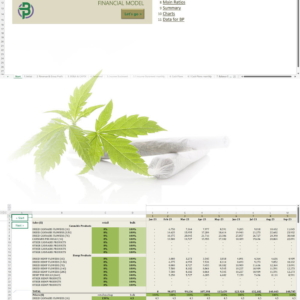

Cannabis Extraction Financial Model Sample (Massachusetts)

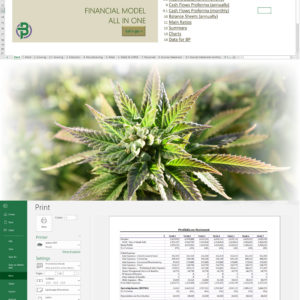

Calculate extraction business costs and profits with our pre-populated cannabis extraction financial models. All you have to do to get started is enter the size of your premises. The model will help you estimate how much it costs to start and operate your own cannabis extraction business, build all revenue and cost line-items monthly over a flexible seven year period, and then total the monthly results into quarters and years for an easy view into the various time periods.

Cannabis Extraction FAQs

Is cannabis extraction profitable?

Profitability depends on many factors, including extraction method and equipment, capacity and location. Profit margins in the manufacturing side of the cannabis industry are more modest than for vertically integrated types of cannabis business due in part to the high median direct costs. On the other hand, the cannabis concentrates market has been steadily expanding in recent years and is projected to expand again between 2023 and 2030, opening the door to new successful businesses.

How much does cannabis extraction cost?

We can use the following formula for a very rough estimate. We will take extraction equipment as our starting point. Then reactors, filters, thermostats and holding vessels will cost 20% of the cost of the extraction equipment. The cost of the solvent recovery system and cannabinoid distillation system is estimated to be approximately 40%. Finally, a buffer of 10% is provided to account for ancillary items.

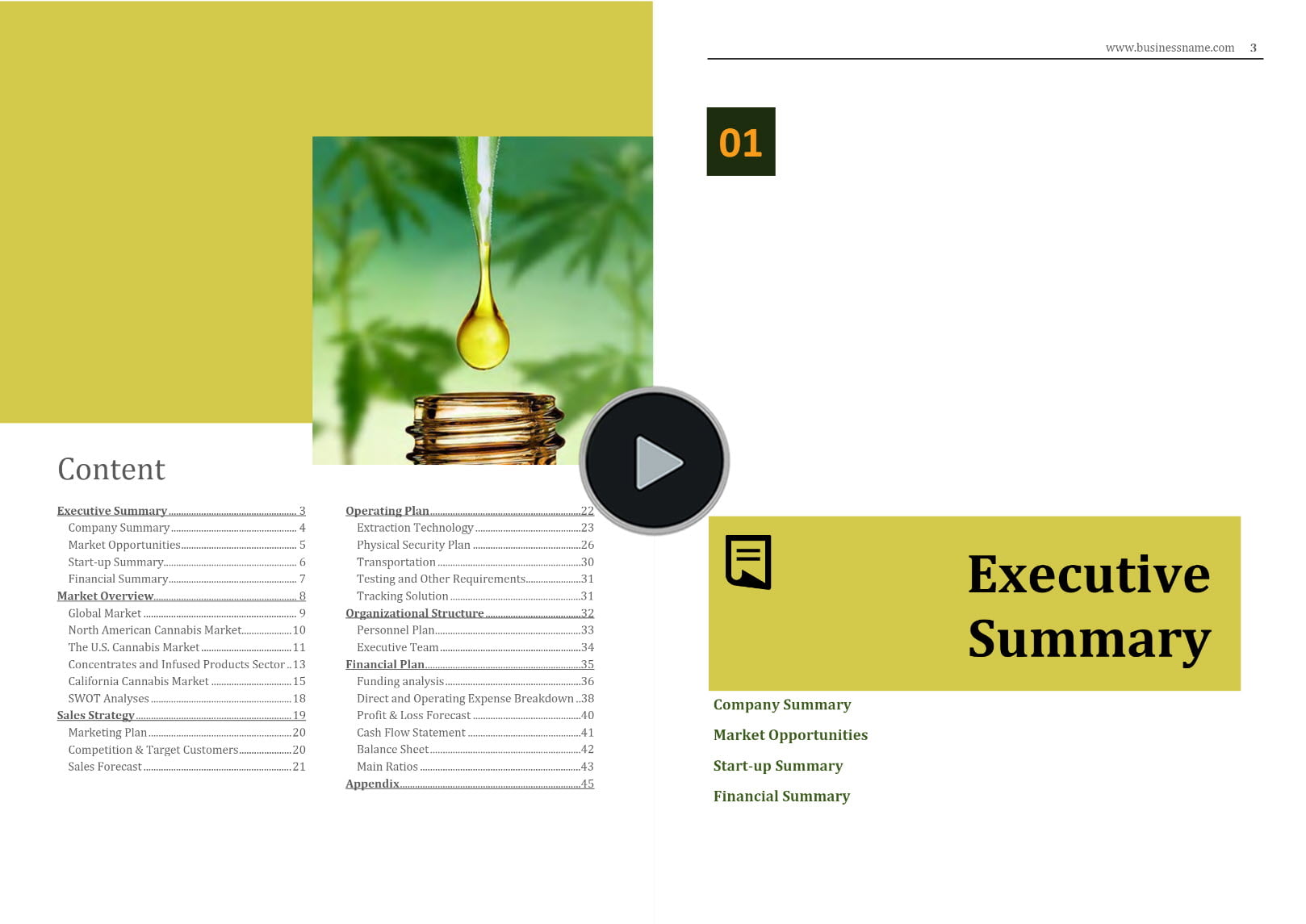

Do you have a business plan for cannabis solventless extraction?

We provide financial models and business plan templates for both solvent-based and solvent-free extraction methods.

'70% ready to go' business plan templates

We also offer Word document and PowerPoint pitch deck templates for your cannabis extraction business.

Should you have any questions, please do not hesitate to contact us.

Cannabis Extraction Business Plan Sample (California)

Business plan templates for a hemp/CBD extraction business are available at hempcbdbusinessplans.com.